Electroplating cleaning agent

Application field: Electroplating cleaning agent is suitable for electrolytic oil removal on the surface of steel, stainless steel, copper, zinc, aluminum and their alloy metal workpieces.

Product Introduction

Electroplating cleaning agents are scientifically formulated from a variety of imported raw materials, with strong emulsification ability, significant oil and dirt removal ability, good water washability, and corrosion inhibition. They can effectively remove oil and grease adhering to the surface of the workpiece, improve the bonding force between the substrate and the electroplating layer, and will not produce explosive phenomena. They are easy to operate, non corrosive to the substrate, low consumption, low pollution, and economical and durable.

Application field: Electroplating cleaning agent is suitable for electrolytic oil removal on the surface of steel, stainless steel, copper, zinc, aluminum and their alloy metal workpieces.

Product Feature

| √ Fast oil and wax removal cleaning speed |

| √ No corrosion or damage to the workpiece |

| √ Long service life of tank liquid |

| √ Water-based safety, easy to rinse, no residue |

| √ Low odor, non flammable and non explosive |

| √ Meets EU RoHS indicator requirements |

Quick to clean, non corrosive, easy to rinse, environmentally friendly, odorless, and not harmful to hands

Physical and chemical indicators

| Appearance | Colorless to slightly yellow liquid | Density | 1.04~1.06g/L |

| PH | 3-5 or 6-9 or 11-13(working fluid) | Secure | Non combustible non corrosive |

| Environmental protection | Phosphorus free, halogen-free, compliant with EU RoHS requirements | ||

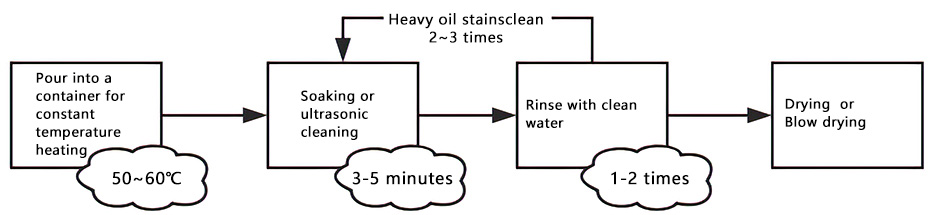

Process Flow

Precautions for use

USAGE

Constant temperature immersion cleaning or ultrasonic cleaning

USAGE METHOD

Dilute in proportion to the working solution, heat to 50-60 degrees, soak at a constant temperature for 5-10 minutes, or clean with ultrasound for 2-3 minutes.For heavy oil contaminated workpieces, extend the cleaning time or use multiple grooves to thoroughly clean them.

MAINTENANCE

1. Regularly check the temperature and liquid level of the tank liquid, replenish water in a timely manner, and add the corresponding proportion of the original liquid.

2. Regularly replace the tank liquid according to the specified time.