Product Introduction

Cerium oxide polishing powder cleaning agent is a water-based cleaning agent formulated from various imported surfactants, corrosion inhibitors, and other additives. It is specially developed for the residual cerium oxide polishing powder after glass polishing. It has a very good chelation dispersion and cleaning effect on the residual cerium oxide particle dirt on the glass surface. It has the advantages of no corrosion to the glass surface, less scratches, non-toxic and pollution-free, and safe operation. Widely used for cleaning optical glasses of silicate, borate, and phosphate types.

Application field: Specially used for cleaning optical glass after polishing and grinding.

Product Feature

| √ Especially effective for cerium oxide polishing powder, with high cleanliness |

| √ No scratches, watermarks, or white spots after cleaning |

| √ The tank liquid has a long service life and will not return to dirt or dirt |

| √ Protect the glass from discoloration, dullness, and damage to the film layer |

| √ Water based safety, low foam type, easy to rinse, no residue |

| √ Meets VOC, COD, and EU RoHS requirements |

Quick to clean, non corrosive, easy to rinse, environmentally friendly, odorless, and not harmful to hands

Physical and chemical indicators

| Appearance | Colorless to slightly yellow liquid | Density | 1.04~1.06g/L |

| PH | 3-5 or 6-9 or 11-13(working fluid) | Secure | Non combustible non corrosive |

| Environmental protection | Phosphorus free, halogen-free, compliant with EU RoHS requirements | ||

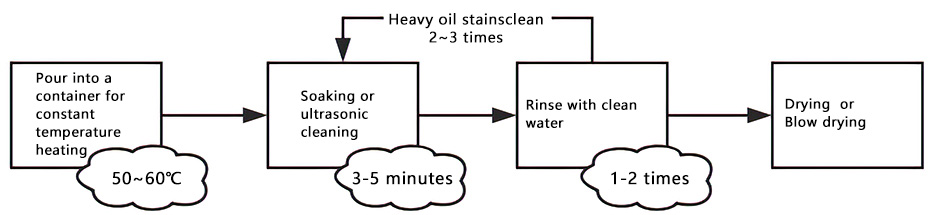

Process Flow

Precautions for use

USAGE

Constant temperature immersion cleaning or ultrasonic cleaning

USAGE METHOD

Dilute in proportion to the working solution, heat to 50-60 degrees, soak at a constant temperature for 5-10 minutes, or clean with ultrasound for 2-3 minutes.For heavy oil contaminated workpieces, extend the cleaning time or use multiple grooves to thoroughly clean them.

MAINTENANCE

1. Regularly check the temperature and liquid level of the tank liquid, replenish water in a timely manner, and add the corresponding proportion of the original liquid.

2. Regularly replace the tank liquid according to the specified time.